Can You Drill or Screw Into a Paving Slab?

Although it’s a pretty durable substance, concrete is easy to drill into with the right tools. If not done correctly, drilling and screwing will weaken the paving slab.

You can drill and screw into a paving slab using a hammer drill. Although it’s unnecessary to water down the concrete while drilling, doing so will make it easier to collect and remove drilling dust. Once you’re done drilling, you may secure objects with concrete screws or special anchors.

This post will discuss how to drill into a concrete slab and the suitable screws to use. Additionally, we will talk about different anchors for securing items to the paving slab.

How To Drill Into a Concrete Slab?

Drilling into concrete is the most reliable way to secure large structures such as cabanas. Usually, you’ll have to use an anchoring instrument after drilling.

This process, however, will leave permanent holes in your concrete. So, make sure you’re okay with this before proceeding with the following steps:

- With a 10mm (0.39in) diameter masonry drill bit, map the hole locations into the paved area. Make the guide hole to at least ¼in (0.635 cm) deep.

- Clean the holes using water.

- Drill anchor holes in the pavement slab using a hammer drill and the same bit.

- Remove excess dirt from the pits.

- Lace a threaded screw into a washer and nut to make the ground bolts.

- Force the foundation bolts through the paving slab’s openings. You can use a drill or hammer in this step.

- Tighten the nut with the appropriate spanner until the fixings are stable. The maximum recommended torque setting is 20lbs/ft (9.1kg/m) or 27Nm.

Can You Screw Into a Paving Slab?

Screwing into concrete is possible if you use durable materials. In certain situations, it requires pre-drilled holes. There are, however, screws that can be driven into concrete without drilling first.

Keep in mind that the tighter you screw into the opening, the more stress you apply to the concrete. This increased strain raises the risk of crack formation. And if you’re not careful, you can break the pavement around the screw.

What Type of Screws Can You Use in Concrete?

Concrete screws are a convenient and strong method of fastening items to concrete. Generally, you don’t need hammering unless you’re using a specific anchor.

These concrete screws have a high to low tread pattern that grips the hole’s sides closely. To ensure a secure connection, use the screw manufacturer’s recommended drill bit and drill the hole about 1/4in (0.635cm) longer than the screw length. This way, the screw won’t reach the hole’s bottom before it fully fits.

Concrete screws are available in diameters of 3/16in (0.476cm) and 1/4in (0.635cm) with lengths of up to 4in (10.16cm). Additionally, you can choose between hex-head and Phillips-head screws.

What Anchors Can You Use in Concrete?

Before positioning your anchors, drill a hole with a carbide-tipped masonry bit. The simplest and fastest way is to use a hammer drill, which creates holes with both bit rotating and concussive strikes.

If you don’t have a hammer drill, you can use a regular electric drill; however, drilling the hole will take at least twice as long.

Hammer-Set Anchors

When binding something comparatively lightweight to concrete, use hammer-set anchors. However, bear in mind that hammer-set anchors aren’t reusable. Also, it’s best not to use these fasteners with crumbly concrete or mortar.

The most significant advantage of hammer-set anchors is their ease of installation. There are no nuts or washers involved. But once hammer-set fasteners are mounted, you can’t easily remove them without damaging the paving slab or the anchor.

Each anchor has an unthreaded pin encased in a metal sleeve. To secure these, position the fixture over the hole, and tap the anchor into the opening with a hammer. When you push the pin into the opening, the sleeve stretches outward, securing the anchor.

The majority of hammer-set anchors need a hole with a diameter of 1/4in (0.635cm) and are available in lengths ranging from 1-3in (2.54-7.62cm).

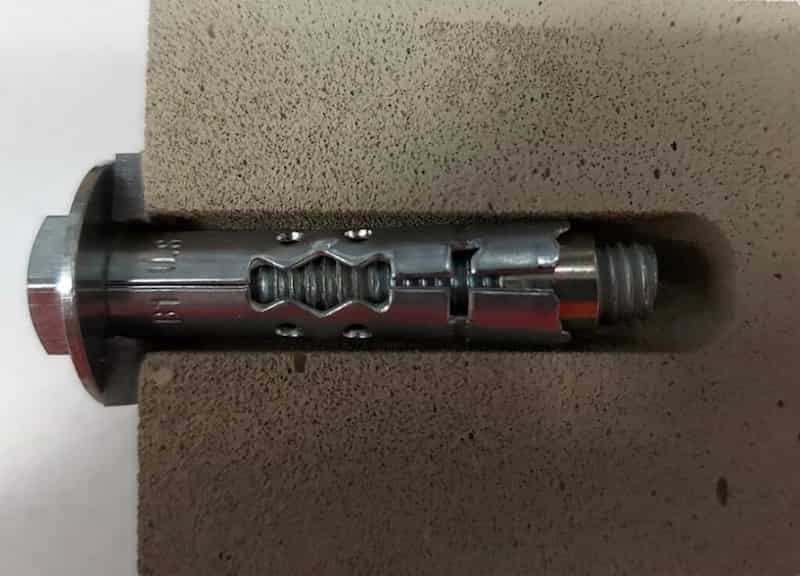

Concrete Sleeve Anchors

Sleeve anchors are male fasteners made up of a threaded bolt encased by an expander sleeve on one side and a nut and washer on the other. Generally, the anchor is threaded into the fixture and through the hole in the paving slab. The sleeves grip the pre-drilled hole surfaces and tighten as the securing bolt is twisted, thus providing the necessary grip.

These anchors come in a variety of sizes and support nearly 200lbs (90.72kg).

Like hammer-set anchors, if the nut is overtightened, the fastener will crack, or the paving slab will break.

- Expansion type anchors used to fasten fixtures into a variety of base materials

Machine Screw Anchors

This female anchor is a fastener made up of a cylindrical base inserted into a pre-drilled cavity. The screw must be placed through the fixture, through the opening, and into the foundation. As the screw goes into the foundation, the base extends to hold the anchor in the cavity. You must secure the screw using a setting tool.

Each machine screw anchor requires a unique setting tool that you have to buy separately. When the setting tool’s lip touches the anchor, the fastener is placed correctly.

Note that the hole size for machine screws is greater than the size of the anchor used.

Lag Shield Anchors

Lag shield anchors are made of a ribbed, tapered zinc alloy sleeve that slips into a pre-drilled hole. As the lag screw gets inserted and expanded into the sleeve, it cuts its thread and presses the shield’s outer wall against the paving slab.

These anchors come in short or long variations. Generally, the more extended version has superior hold power in less dense base materials. At the same time, a shorter lag shield performs well in more rigid base materials and helps shorten drilling time.

Given the soft metal wedge’s pliability, lag shield anchor bolts perform best in conditions where the hold has to withstand vibration. Plus, you can remove objects secured with lag shield anchors easily.

Their main drawback is that the hole size must be exactly the size indicated for that particular anchor, or it won’t work.

How To Avoid Cracks When Drilling Into a Concrete Slab?

When digging into concrete, it’s essential to use proper techniques to prevent cracks. Here are the steps to follow:

- Always keep the drill parallel to the paving slab.

- Avoid overdriving the drill and work using light pressure to allow the bit to do its job.

- Check to see if the bit is rebounding from the bottom of the hole. If you try to force the drill through, you may end up creaking the slab.

- Don’t drill any more than necessary. A simple rule of thumb is to measure the anchor or bolt before inserting it into the concrete.

- Add a sheet of tape to the drill bit and stop drilling when you hit the marked area.

Final Thoughts

Learning how to drill into concrete can seem daunting, but with the correct equipment and techniques, what seems to be a difficult job can be made easier. And if you don’t have building experience, Home Depot has a video that will show you how to dig into a paving slab:

If you’re having difficulty pushing the screw through, it’s either that the opening isn’t big enough or that there’s too much dirt within. With this in mind, consider extending or cleaning the hole.

Learn more!!!! How To Attach Pressure Treated Wood To Concrete