Cement Board vs. Drywall: The Ultimate Comparison

Drywall and cement board are two of the most common materials used in the construction industry. They’re both fairly resistant to moisture and natural wear, but some builders prefer one over the other. How are you supposed to know if you should use drywall or cement board for your projects?

When it comes to cement board vs. drywall, cement board is much more waterproof and durable. However, drywall is easier to work with and it’s not nearly as expensive as cement board. For most applications, cement board is used behind showers/bathtubs and outside and drywall is used inside.

Throughout this article, you’ll also learn the following info about cement board and drywall:

- Comparing and contrasting the two materials

- Which one you should use for your building

- Which is better overall

Is Cement Board the Same as Drywall?

Cement boards and drywall are quite different, but with a few things in common. Before we go on to have an in-depth look, some definitions would be helpful.

So, what’s a cement board, and what’s drywall?

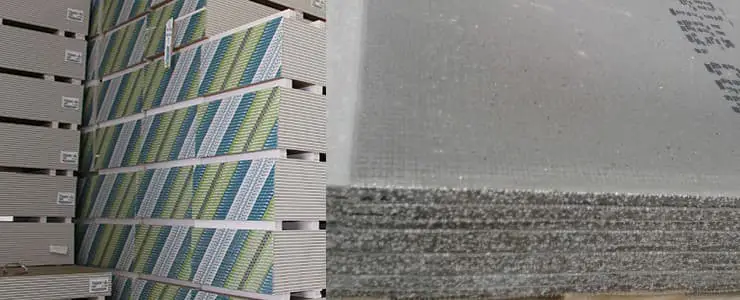

Cement Board: According to Carolina Services, cement boards are inexpensive cellulose-containing sheets made up of reinforced glass fibers and cement slurry. Primarily, cement boards are suitable for countertop underlayment, and they enhance the durability of tiling and flooring installations. They are a top choice for use in high humid areas and are available in 3’x5′ and 4’x8′ panels, with a variation between 0.25″ and 0.5″ thickness.

Drywall: Drywall or wallboards are made of gypsum panels compressed in between standard paper sheets. They were developed to provide a better alternative to plaster and lath interior wall installations. Like cement boards, drywalls are suitable for use in highly humid regions such as bathroom walls.

Are these two the same?

Both materials come in sheets and are suitable for use in humid areas. That’s just about their only similarities. The durability and strength of either backing material in humid areas are quite distinct. In general, cement boards and drywall are made from different components and are not the same.

Differences Between Cement Board and Drywall

Although these two construction materials are suitable for humid regions, one exhibits more strength and durability than the other. In simple terms, their ability to stay in shape under lengthened exposure to moisture varies – and that’s one of the stand-out differences. Before we go on to examine several other differences, let’s quickly take a detailed look at the factor that influences their responses to moisture.

Cement Boards are waterproof and water-resistant: By definition, water-resistant materials prevent water penetration to a certain extent but not entirely. On the other hand, waterproof material is coated and protected against water damage.

Combining these two attributes guarantees a high level of protection and ensures that cement boards don’t get mildew and mold when exposed to moisture. Of course, this is attributed to the fact that cement boards’ base material is cement slurry and fiberglass.

Drywalls are just water-resistant: Drywalls, unlike cement boards, are only water-resistant because of their gypsum core. In other words, a lengthened exposure to water will result in mildew and mold, and eventually, breakage and rot.

Other differences include:

Durability

In terms of durability, cement boards are better than drywalls. Due to their cement and fiberglass base material, cement boards are more impact—resistant and more durable than drywall (made of gypsum and paper sheets). A paper sheet is an organic material, and it’s susceptible to mold when in constant contact with moisture, hence, the not-so-impressive durability of drywalls.

In the event of a failure to the caulk and grout of cement boards, the walls are still waterproof; therefore, there’s no chance for rot. But in drywalls, a damaged paper sheet exposes the gypsum to moisture and potential damage.

Installation Requirements

Drywalls are lighter than cement boards, cut easily, and are much easier to handle in DIY projects. But for cement boards, they’re heavier, tougher to cut, and challenging to install and require professional installers’ attention.

Material Composition and Sizes

Cement Board: made of glass fiber and cement slurry; available in 3×5′- 4×8′ sheets and 0.25-0.5″ thickness.

Drywall: made from paper sheets and gypsum; available in 4×8′- 4×10′ sheets and 0.5-0.625″ thickness.

Use Cases

Drywalls are best suited for interior applications because of their fragile gypsum core, while cement boards thrive well when utilized externally due to their cement and fiberglass makeup.

The question of ‘which is better’ would be subject to both backing material’s performance under certain conditions. Let’s examine some of these conditions:

Eco Safety: Cement boards are revolutionary products made from cement and fiber, both organic substances and are very much environmentally safe. They are certified eco-friendly right from the stage of manufacturing to final disposal, and they help to lower the heat island effect.

For drywall, the reverse is the case. Although recyclable and versatile, its production process utilizes a considerable amount of energy and eventually causes land toxicity and water eutrophication. The better choice, in this case, would be cement boards.

Porosity: Drywalls are more porous than cement boards. This factor accounts for why it’s easier to cut the former, even with a knife, and the latter requires a saw.

Ease of Installation: Cement boards are quite technical to install and must be handled by professionals. Now, that could be a drawback for DIY enthusiasts. But for drywalls, the installation process is simple, smooth, and suitable for DIY projects. If you need something you can install all by yourself, drywalls are better or you.

Durability

Without mincing words, cement boards are a better choice if you need something that’ll last longer. They’re more flexible, compact, and efficient when compared to drywall. The durability of cement boards is attributed to the mesh-like and compact molecular structure of their makeup. Again, if you desire durability, cement boards check that box.

Weather Resistance: Three elements are always of core concern whenever weather comes to play – heat, wind, and water. Cement boards perform excellently well when exposed to any of these elements of nature. The fiber in cement board confers it to hold up better against heat compared to drywalls.

Cement boards are, by default, highly resistant to water damage, while gypsum-based drywalls require a coating to attain some degree of water resistance. If you desire an exterior cladding, you’ll want to be sure that whatever material you choose stays in shape regardless of the prevailing weather conditions. Cement boards check that box too!

So, which is better?

In general, for external applications, cement board is your best bet, but for interior applications, drywalls will do a good job. More specifically, cement boards will do just as much as drywalls would, and even more!

In other words, you could choose a cement board for both interior and exterior installations. Hence, it’s safe to conclude that cement boards are better than drywalls due to their dual applicability. However, it’s best to make a judgment based on location and requirements.

What is the best option, Drywall or cement board for fireplace

Conclusion

Cement board and drywall can be used in almost any building. Remember that you need to be a bit more professional when you’re dealing with cement board. While drywall is easier to handle, it can’t withstand long-term humidity like cement board can. Which one is better depends on what you’re using it for, what your budget is, and your current knowledge of construction.

Sources

- https://www.marylandbathroom.com/cement-board-over-green-board/

- https://www.zmartbuild.com/fiber-cement-board-vs-gypsum-board/

- https://www.ecopro.co.in/heat-island-effect-alarming-issue-of-mega-cities/

- https://www.ecopro.co.in/why-fibre-cement-boards-are-better-than-other-drywall-options-for-exterior-cladding/

- https://carolinaservicesinc.com/cement-board-used/

- https://www.hunker.com/12003239/differences-between-wallboard-drywall-and-cement-board